Scada

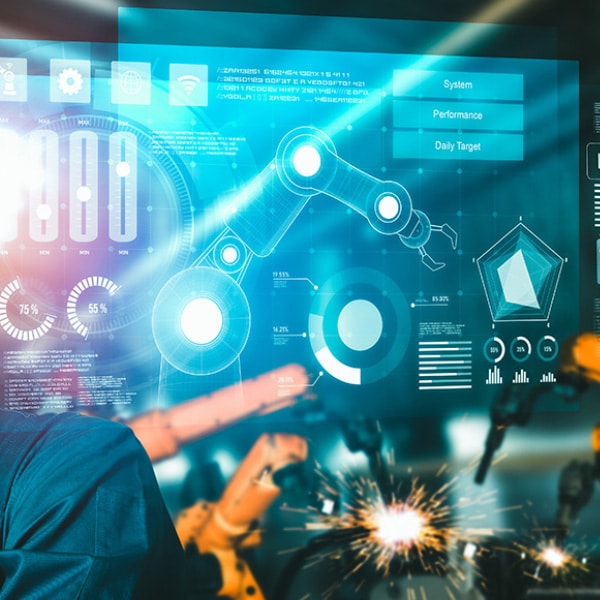

SCADA (Supervisory Control and Data Acquisition) is a centralized software platform used to collect data from sensors and I/O devices, visualize processes in real-time, and allow for remote control.

The system is widely used in manufacturing plants, energy and water infrastructure, HVAC, traffic management and other critical OT environments. Modern SCADA systems are often extended with IIoT features such as edge data buffering, subscription-based updates (publish/subscribe) and cloud integration (e.g. MQTT, OPC UA).

When is remote connectivity relevant?

Operators use SCADA to monitor critical parameters (pressure, temperature, flow), receive alerts for deviations and analyze historical trends to optimize operations.

Via dashboard and HMI, you can change parameters, perform preparation or stop/start operations - even in remote locations.

SCADA systems collect tagged data from PLCs and RTUs (often over Modbus, OPC UA or IEC 61850) and send it to control rooms, cloud platforms or analytics solutions.

For large networks with many serial processing units, agent-mode gateways are used to reduce query intervals, improve performance and minimize network load.

Benefits in OT environments

Real-time monitoring

SCADA creates overview in control rooms with live data and status

Alarm management with history

It is possible to define alarm limits, trigger notifications and lead failure analysis based on time series

Remote management and flexibility

Operation can be done remotely through secure communication channels

Larger network scaling

IIoT features like edge buffering and cloud integration make SCADA future-proof and scalable